Solve Office Space Problems With KABTech Modular Offices

An automotive product and parts manufacturer was looking to improve their work facility with a new office space. The manufacturing plant was dealing with noise control problems because their quality control work area was located out in the open production area of the facility and there was no separation between this workspace and the production area. The company needed to make a change that would help prevent the loud machinery from disrupting their team.

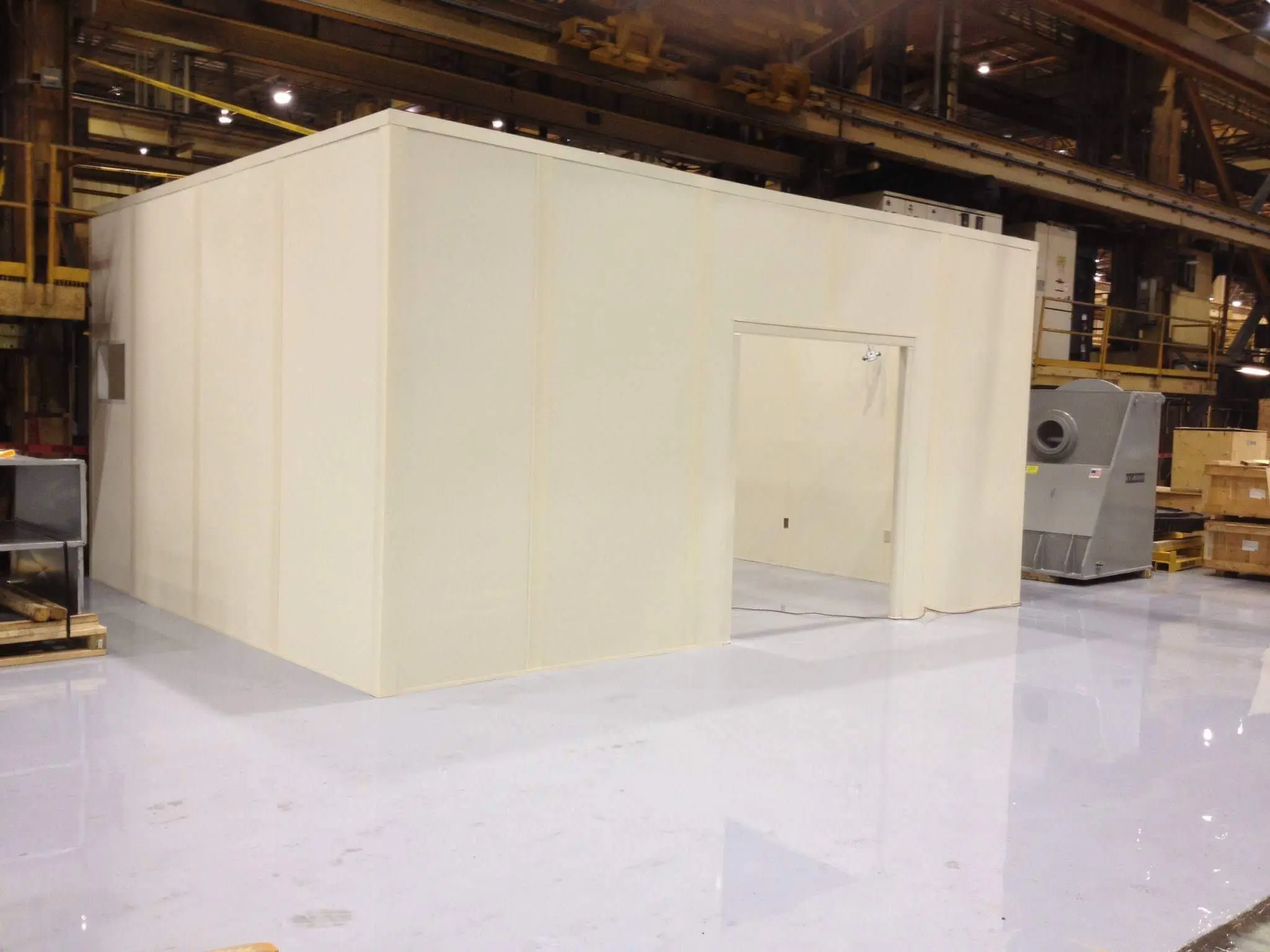

To solve this problem, KABTech proposed a modular in-plant office that could be used as comfortable laboratory and workspace area for the quality control manager and support technicians. With this enhancement, they would be able to work in a temperature-controlled environment without being subjected to the distracting plant noises and debris-filled air.

As an alternative to constructing a modular in-plant office, the parts manufacturer could have considered building a standard stick-built office. However, there would have been a few disadvantages with this option. To begin with, the high noise levels and dust would still be a problem. The planning and construction phases would have also been a much longer process and could have disrupted the facility’s production capabilities. For these reasons, the proposed in-plant modular office was a much more desirable option for the client.

Project Installation:

After mapping out the office design, KABTech went to work constructing the in-plant office and sound-proof workspace. We included an electrical package with the office which featured a data box, room lights, and multiple outlets.

Our crew was able to install the in-plant modular office in a short 3-day period, to minimize any interruptions to the facility employees. The installation process included building the enclosure, installing the ceiling, putting in the HVAC unit, and wiring all electrical components to a junction box. While working on the project, we were happy to accommodate the client by building directly over their marble testing table which was used for leveling measurements. The testing table would have been too wide to fit through a standard door. However, our installation team was able to build conveniently around the table and include it inside of the modular office.

End Result:

The automotive manufacturing facility was extremely satisfied with their finished in-plant modular office. The company was impressed with both the speed of the installation and the advantages of having a secluded workspace. Their quality control manager and support technician are now able to retreat from the production floor to a comfortable office space without being subjected to unwanted noise and dust.

Want to learn more about our modular offices and industrial interior solutions? Contact us today to find out how KABTech can develop, build, and execute the design of your next in-plant office or structural mezzanine project.

continue reading