Looking for elevated industrial work platforms that can be erected inside your industrial plant?

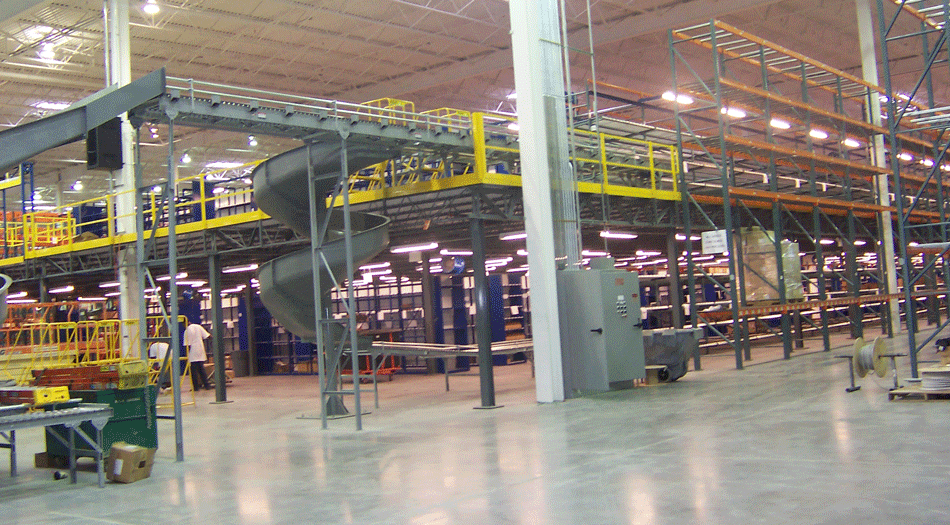

Since 1985, KABTech USA has been a leading manufacturer in designing and delivering custom-built industrial platforms. We understand that in manufacturing, warehousing, and other various commercial settings, every square foot matters. KABTech’s platforms are engineered for durability, flexibility, and compliance with industry standards, helping you create efficient, safe workspaces.

We offer modular and custom-designed work platforms, raised equipment platforms, raised crossovers, or walkways that bolt into place.

Work Platforms

Equipment Platforms

Raised Walkways

What is a Work Platform?

A work platform is a temporary or permanent structure that provides elevation, stability, and access to otherwise hard-to-reach areas. These platforms are critical for facilitating maintenance, assembly, and operational tasks within industrial environments.

KABTech’s work platforms are built with modular, flexible designs, enabling easy customization to match your facility’s specific needs.

Structural Equipment Platforms

At KABTech, we specialize in raised and structural platforms, making us a leader in the industry. Our range of structural raised platforms is custom-designed to meet your specific load and use requirements.

Additionally, our prefabricated and pre-sized equipment platform kits can be quickly assembled or installed by our skilled KABTech professionals, ensuring they perform reliably for years to come.

With years of experience in designing, shipping, and installing, our team can create:

- Single and multi-level industrial platforms

- Machinery and equipment platforms

- Structural mezzanines

- Stair towers and stairs with landing platforms

- Raised walkways and industrial crossovers

- Mezzanine offices and observation rooms

We’ve developed these solutions for many top industrial manufacturers. Watch this video for more details about our industrial work platforms.

Custom Platforms and Walkways Are No Problem!

At KABTech, we don’t just stop at industrially raised work platforms — we also specialize in custom-designed prefabricated metal stairs and landings. Whether you need access to existing raised decking or stair towers, we tailor our solutions to fit your specific space and equipment requirements, ensuring safe and convenient elevated access.

Our prefabricated platform structures and modular steps are designed with your unique needs in mind, taking into account load points and spatial constraints. This level of customization allows us to create solutions that seamlessly integrate into your facility while maximizing efficiency and safety.

In addition to our industrial platforms, we offer innovative noise control enclosures and barriers that help insulate raised equipment and manage noise levels on your platform. This is particularly beneficial in industrial settings where equipment noise can disrupt operations and impact work environments.

We take pride in providing some of the most versatile and thoughtfully designed industrial platforms available today. Our dedicated technicians go the extra mile to assist you with every aspect of your modular platform project. We prioritize understanding your needs so we can deliver a quick and accurate quote without delay.

At KABTech, your project isn’t just another job — it’s an opportunity for us to showcase our commitment to quality and customer satisfaction. Let us help you create a safe, efficient, and customized workspace that

Landings For Surface Equipment

We also address the problem and offer solutions for safe and economical stairways and landings for surface equipment platforms and raised, top-load hopper platforms, as well as pre-assembled second-story gangways and stair towers.

Our engineers will ensure that your industrial work platform, equipment platform, or structural mezzanine meets your expectations. All of our platforms not only meet but exceed all of OSHA’s requirements for raised work platforms, walkways, and industrial stairs. From anti-slip surfaces to reinforced railings, each platform component is designed to provide the highest level of workplace safety.

The Advantages of Pre-Manufactured Industrial Raised Platforms

Pre-manufactured industrial raised platforms offer a more economical solution than hiring local fabrication shop contractors. One of the primary benefits is cost efficiency. By choosing a pre-manufactured option, you can significantly reduce your overall project costs without compromising on quality or safety. This is largely due to our streamlined production processes and bulk purchasing of materials, which allow us to pass those savings on to you.

In addition to cost savings, our extensive experience in platform design means you will receive a safe, robust platform that meets all industry standards. Our skilled engineers and designers utilize their expertise to create functional and tailored platforms that meet your specific needs. This level of proficiency ensures that you won’t just get any platform; you’ll receive a meticulously crafted structure that enhances your workflow and maximizes safety.

Another key advantage is speed. Pre-manufactured platforms can be delivered and installed in half the time it typically takes to custom-build one at a local fabrication shop. Our efficient manufacturing process, combined with precise planning and execution, means that you can get your operations up and running faster. This is especially crucial in industrial environments where downtime can be costly.

By opting for pre-manufactured platforms, you can rest assured that you are making a smart investment that balances quality, safety, and affordability. Let us help you elevate your workspace efficiently and effectively with our expertly designed industrial-raised platforms.

Industrial Platforms and Structural Mezzanines by KABTech.

KABTech’s raised industrial platforms and mezzanines can take nearly any form, shape, or size you require.

Our unique modular bolt-through design allows the platform beams, columns, and cross members to be installed easily and quickly. Structural modular platforms allow for custom beam sizing to carry load points precisely where they are needed without oversizing the entire structure.

The latest structural beam designs will span greater distances and carry higher load-bearing capacity than common prefabricated work platforms can offer.

Traditional platforms often require significant time and expense to design, fabricate, and install. By choosing KABTech’s pre-engineered platforms, facilities save time and avoid the costs associated with custom fabrication. This efficiency is particularly advantageous in time-sensitive industries, allowing businesses to implement necessary equipment without sacrificing lead time.

Versatility is one of the great benefits of modular construction.

Industrial raised platforms can be constructed with metal bar grate flooring or poured concrete for a more permanent, durable, and long-lasting surface.

Mezzanine and raised industrial platform systems, other than poured concrete floor structures, can be disassembled, relocated, or reconfigured for future plant expansion.

This allows for structure enlargement, relocation, or equipment modifications without wasting any part of the original platform or platform stairs and landings as redesigns are required.

Industrial raised platforms can be constructed with metal bar grate flooring or poured concrete for a more permanent, durable and long lasting surface.

A wide variety of colors and finishes are also available to keep your custom-raised work platforms looking good and performing well for many years, even when exposed to the elements.

For a permanent and durable finish, the floor panels and flooring options can be made of wood, bar grating, steel plate, or poured concrete.

Many Uses for Work Platform Structures and Raised Industrial Mezzanines

From large-scale manufacturing to smaller commercial operations, industrial platforms serve a multitude of functions. Here’s how some industries benefit:

- Manufacturing Plants: Platforms in manufacturing settings provide safe access for machine operators, technicians, and supervisors. Mobile platforms allow flexibility on busy production floors.

- Warehousing and Storage: Work platforms provide efficient storage solutions by utilizing vertical space, which is especially useful in distribution centers with high-volume storage needs.

- Maintenance and Inspection: Mechanical platforms elevate essential equipment, such as HVAC systems, for easy access during repairs, ensuring minimal disruption to operations.

- Assembly Lines: Single-step platforms and mobile units improve efficiency on assembly lines by positioning employees at optimal working heights, reducing strain and fatigue.

Lifts for Raised Work Platforms

Raised structural platform systems make adding second-floor balconies, elevated walkways, and multiple industrial stairways more economical than conventional construction methods and can be completed in only a fraction of the time.

What Options Are Available For Industrial Platforms and Platform Mezzanines?

KABTech offers numerous customization features to meet the diverse needs of industrial applications:

- Custom Designs: Tailored to fit complex industrial setups.

- Versatile and Durable: Built for longevity and future expansion.

- Modular Construction: Easy, bolt-together assembly.

- Finish Options: Weather-resistant treatments for indoor/outdoor use.

- Prefabricated Elements: Metal stairs, landings, and handrails.

- Load Capacity: Customizable to meet heavy-duty needs.

- Flexible Flooring Options: Choices include resin, plywood, metal grating, and concrete.

- Specialty Applications: Food-grade platforms, military specifications, and raised office integration.

Explore a complete range of configurable options for seamless industrial solutions with KABTech.

Requirements For Modular Work Platforms and Equipment Platforms

Our experienced designers will carefully calculate the requirements for footings, spans, and load-bearing columns to ensure your order is accurate from the start. We can also adjust deck heights to meet your specific platform requirements.

For spaces with limited room for stairway runs, we offer prefabricated stairways and landings tailored to your unique application. Plus, we can integrate extra supports throughout the platform to address any equipment load point concerns. Our industrial work platforms are designed to fit seamlessly around existing equipment, buildings, or structures, making the most of your available workspace.

Considerations When Planning an Industrial Work Platform

When designing an industrial work platform, start by defining its primary use and location:

- Usage and Location: Consider ceiling height (ideally, at least 14 feet) and decide if it will support equipment, in-plant offices, or multiple applications. Determine if it will attach to an existing structure and whether future expansion should be included.

- Floor Capacity: Ensure your floor can support the platform’s load. A 6-inch slab with reinforcement is typically standard, but a slab and soil analysis will confirm if additional footings are needed.

- Column and Base Plate Design: Size columns and base plates correctly to manage the load. Concrete footings may be necessary for high loads or low floor capacity. Also, choose a column layout that won’t disrupt floor activity, such as forklift traffic.

- Code Compliance: Confirm applicable codes — especially for states with seismic requirements — and ensure the design meets IBC, AISC, ASTM, and OSHA standards. A PE-stamped platform design expedites permit approval and meets necessary structural standards.

- Platform Capacity and Specifications: Communicate platform support and mounting requirements to engineers for proper code categorization.

- Platform Types: Decide between modular (pre-fabricated, standard dimensions) and custom structural platforms. While modular units come pre-sized, custom platforms are tailored to exact specifications, including columns, beam spans, and added features like stairs and handrails.

Why Industrial Platforms Matter

Industrial platforms are crucial for any facility requiring elevation, durability, and versatile space. From mobile work platforms for easy relocation to corrosion-resistant aluminum options, KABTech provides solutions designed to boost productivity and safety:

- Boosted Productivity: Platforms bring personnel closer to high-reach tasks, improving workflow.

- Safety Compliance: OSHA-compliant designs offer safe, stable access, reducing the need for custom engineering.

- Flexible Solutions: Mobile or fixed, single- or multi-level, KABTech platforms integrate seamlessly with large and small spaces.

Get Started with KABTech

KABTech USA is committed to delivering high-performance platforms tailored to your facility’s specific needs. Whether you require mobile work platforms for flexibility, aluminum platforms for durability, or steel platforms for strength, KABTech has the solution. Our expert team is ready to assist you every step of the way, from initial consultation through to installation.

Contact our expert team today at 888-370-9216 to learn more about how our platforms can transform your space into a safer, more efficient environment.

Frequently Asked Questions

What is a work platform?

A work platform is a raised structure designed to provide stable elevation and facilitate access to high-reach areas for various tasks.

What is an equipment platform?

Equipment platforms are structures that support industrial machinery, providing safe, elevated spaces for maintenance and operation.

What is the advantage of steel platform construction?

Steel platforms offer unmatched stability and are ideal for heavy-duty applications. They are particularly suited for permanent installations that require load-bearing strength.

What is a mechanical platform?

Mechanical platforms support critical infrastructure, such as HVAC systems, compressors, and other industrial machinery that requires routine maintenance access.

How do mobile work platforms increase productivity?

Mobile platforms can be moved between locations, providing stable elevation where it’s needed most. This flexibility boosts productivity, especially during multi-phase projects.

continue reading