Quick Install Modular Cleanrooms

Modular cleanrooms provide unique benefits to manufacturers who want to install a cleanroom application to their facility.

If you have a limited budget and a short amount of time to get your cleanroom project completed, modularly constructed cleanrooms by KABTech will be the way to go. Along with saving time and money, modularly constructed office units by KABTech create a more efficient cleanroom simply because of the process in which modular clean rooms and in-plant office rooms are built.

If you have a limited budget and a short amount of time to get your cleanroom project completed, modularly constructed cleanrooms by KABTech will be the way to go. Along with saving time and money, modularly constructed office units by KABTech create a more efficient cleanroom simply because of the process in which modular clean rooms and in-plant office rooms are built.

Unlike Modular Construction Methods, a typical construction process will start with metal studs and gypsum wall board. Then to create a clean room environment, the walls, joints, ceiling, and door openings will have to be treated with seals and coverings to prevent air and dust particle movement between compartments. Even lighting and electrical boxes need special care to seal correctly.

For conventional construction to get it right, it will be expensive and time-consuming.

Now Let’s Look at Modular Cleanroom Construction.

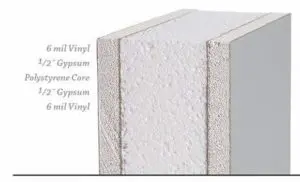

Starting with the wall construction, the basic modular cleanroom wall choices are foam filled with gypsum shell inside and out finished by fiberglass reinforced panels, or a choice of vinyl or metal.

Starting with the wall construction, the basic modular cleanroom wall choices are foam filled with gypsum shell inside and out finished by fiberglass reinforced panels, or a choice of vinyl or metal.

Modular Cleanroom Wall Advantages

- Solid filled foam core means no air movement within the walls.

- Gypsum shell means a sturdy, sound deadening wall.

- FRP, vinyl or metal over panels means durable, dust and moisture resistant surface.

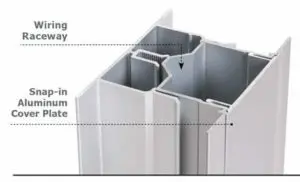

- Electrical circuits are enclosed in the sealed columns and channels.

- Even though the walls are dismountable, the joints at the floor, ceiling, and columns are sealed air tight.

Modular Cleanrooms Are Easy to Incorporate Options

The modular cleanroom units accommodate your choice of options including HVAC, partial filtration systems, mechanical fire control systems, computer wiring conduit and more.

Modular cleanrooms also offer a variety of Door and window options with weather tight seals.

The modular cleanroom panels and trim come completely color coordinated with a large selection of colors to choose from so painting and finishing after assembly are not necessary.

All the modular cleanroom components are manufactured in a controlled factory environment and built to your size specifications. When you receive your per-manufactured modular cleanroom, it is pre-sized and ready to assemble. During assembly, you will not have the mess and waste that you have with the typical cleanroom construction process.

Easy, simple to follow assembly instruction allow the modular cleanrooms to be assembled quickly!

Adding integrated electrical systems allow the modular cleanrooms to be connected as the walls are installed and contain their own power circuit panel.

Because all the modular office components are already built when you receive them, fewer workers are required to assemble the room units.

It is easy to see why modularly constructed cleanrooms have all the advantages over typical construction. Let’s compare the benefits:

- Construction Benefits

- Time Saving Benefits

- Cost Savings

- Quick Ship Ordering

- Install Yourself Option

Modular Cleanroom Time Saving Benefits

The time-frame process to build a clean room for your business using “Standard Construction Methods” will look something like this.

- To complete and approve the clean room plans will take between 6 to 8 weeks.

- Securing a contractor, purchasing materials and site preparation will take between 4 to 8 weeks.

- The actual construction, clean up and testing of the room, allow 10 to 20 weeks.

- Typically between 20 and 36 weeks for the usual building process to be completed.

Obviously, in most in-plant upgrades and modifications, this amount of time is not acceptable!

Coordinating all the construction teams required to complete the job on a schedule is difficult. Contractors know this and will figure in extra time to allow for multiple construction companies to align their plans and coordinate the completion date.

Modular Construction Cleanrooms Look a Little Different

Because the modular cleanroom components are manufactured in a controlled environment, the office units are more economical to build and are produced faster, with significant value & quality.

The time-frame to complete a typical 1500 SF modular cleanroom will be closer to this scenario.

- Completion and approval of shop drawings between 1 and two weeks.

- Process the order and produce the modular cleanroom components including packing and shipping between 4 and six weeks.

- The site can be prepped during this time, so all will be ready when the unit arrives.

- Assembly process that requires a much smaller construction team and time for testing 4 to 6 weeks or less.

9 to 14 weeks at less cost is an easy choice!

Some KABTech installed cleanroom projects have been completely installed in just three days!

When you compare time to completion, project cost and less factory downtime you begin to see the enormous advantages of modular in-plant offices and modular cleanrooms.

Dis-Mountable Walls Maintains Your Investment

Along with this, conventional construction cannot be dismounted and relocated or reconfigured the way modular cleanroom units can when your business expands or upgrades.

Upgrades with conventional construction will waste all the previous clean room investments. It will even cost more money to have removed and discarded.

Modular cleanrooms have removable walls and can be dismounted, moved to a different location and reassembled. Very little of the original investment is lost.

An appliance, lighting and power systems manufacturer contacted KABTech, a leading modular office supplier, to supply the needed cleanroom for their facility upgrade.

Because of the company manufacturers sensitive equipment, it was vital for them to have a clean and controlled environment to limit the level of pollutants and contamination around their products. The manufacturing company also did not want to delay their production to undergo the building renovations.

KABTech suggested constructing a customized modular cleanroom for the facility, which would provide them with a clean and comfortable production climate without disturbing their employees.

Project Installation:

Building a modular cleanroom, instead of a standard cleanroom, was a more appealing option for the manufacturing facility because it drastically reduced the project cost and completion time.

Soft Wall Cleanroom Are Available Through KABTech

In certain circumstances, such as when a company wants to monitor their clean room activities effectively, KABTech would have suggested implementing a soft wall cleanroom with translucent walls.

Softwall modular cleanrooms are often a more cost-effective and flexible solution as they are expandable and easy to disassemble and move. However, in this case, KABTech went with a hard wall modular cleanroom because the manufacturer required a more permanent and secluded work environment.

KABTech built the modular cleanroom 15 feet high and used FRP (fiberglass reinforced plastic) panels which were laminated on both sides. We used FRP instead of aluminum honeycomb, steel, or high-pressure laminate panels because they reduce the chance of dust entering the enclosure and are incredibly easy to keep clean.

KABTech also installed a gasket ceiling grid system to decrease the risk of debris entering the cleanroom and provides a tight seal around the work area.

Adding Air Temperature and Filtration Control

An HVAC system with HEPA filters was also incorporated in the modular cleanroom to ensure that the building would remain sterile and temperature controlled. In the case that there was any air leakage in the walls, the air would be pushed out, and the room would remain uncontaminated.

Custom Lighting and Electrical System Requests

The manufacturing facility also wanted to have special lighting and equipment set up in their modular cleanroom. Usually, when an electrical system is included in a project, it takes a bit longer to install. However, by using a modular electrical system for the outlets and lighting, we were able to decrease the time of the installation and successfully finish the project within a short “three-day span.”

KABTech successfully custom configured the modular cleanroom to meet specific needs of the manufacturing facility by the scheduled project completion date. Overall, the manufacturer was very pleased with the end results of the project, and they can now say that they operate in a contamination-free work environment.

Environmentally Controlled Modular Cleanrooms

Adding a Cleanroom, Quiet Office Space, and a Conference Room

KABTech created a 3-phase plan. First, we installed a 28x22x8 environmentally controlled, modular cleanroom for medical testing equipment. Next, we built-in a 34x24x8 temperature controlled room for the office staff’s cubicles. Finally, we added a 12x24x8 environmentally controlled conference room.

We used VCHB (Vinyl-Covered Hardboard) Modular Panels for each of these. Modular electrical wiring was included.

In only ten days, KABTech transformed this customer’s warehouse into valuable, serviceable space.

Modular Cleanroom Options

Modular Cleanroom Options

- Many wall surfaces including vinyl over gypsum, FRP, Melamine, painted sheet metal and more.

- Wall stud features to accomplish longer clear spans and second-floor options.

- Room temperature and humidity level controls.

- Custom designed floor plan layouts.

- Many choices of door and window designs to choose from.

- Complete pre-wired electrical systems including circuit panel.

- Many options for HVAC and air filtration systems.

To learn more about “Modular Cleanroom Applications” from KABTech, contact a representative today.

We are standing by to assist you with any modular in-plant modification need you may have including two story offices and mezzanines with raised offices.

KABTech provides everything from mezzanines and industrial platforms, In-plant offices, guard shacks and pump houses to material storage racks and security cages and more. You will find our pricing to be extremely competitive and our customer service to be top shelf.

Modular Cleanroom Options

Modular Cleanroom Options